Sledding is on trend: Both as an affordable alternative to skiing and as an original and uncomplicated winter pleasure for children and adults, sledding is extremely popular. As a result, the range of sleds in supermarkets and sports shops has increased significantly. However, these are mostly cheap products from Eastern Europe or Germany. The joy of such "bargains" often does not last long: inferior wood, cheap materials, and poor workmanship cause many of these seemingly cheap sleds to soon fall apart. Warped runners or a wobbly frame then significantly dampen the sledding fun and can even cause accidents.

Sled making - Genuine craftsmanship with tradition

It is clear that a sled can only be so cheap if there is significant cost-cutting in materials and working conditions. Therefore, sled builders in Tyrol and South Tyrol do not even attempt to keep up with the cheap competition, but instead prefer to focus on proven quality. Naturally, this comes at a price, but a high-quality sled can easily last up to 50 winters. This means that the slightly higher initial cost is quickly amortized for the buyer, and in the long run, they have actually acquired the significantly cheaper product.

Sledding in Tyrol and South Tyrol is not only a leisure activity, but also has a great tradition as a competitive sport. Numerous Olympic champions, world and European champions in both luge racing on the artificial track and natural track luge come from the two Tyrolean regions, such as the current world champions in the doubles event, Andreas and Wolfgang Linger, or the double Olympic champion Armin Zöggele. This long tradition also results in an enormous amount of experience in sled building, from which even the hobby sledder benefits.

Custom Manufacturing

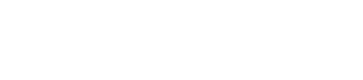

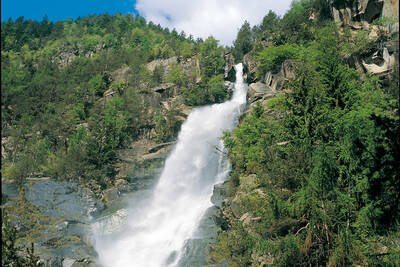

The right material is a prerequisite for a good sled. The most commonly used woods are beech and ash, each with different advantages. Aluminum can be an alternative, especially because of its low weight. The processing must also be appropriate: laminated wooden runners and longitudinal bars are a quality feature and ensure long-lasting stability. If the runners are bent using steam, this must be done with the appropriate care. A lot of know-how is required in sled building, as good maneuverability and directional stability do not come automatically. Although many manufacturing steps in sled building are now done by machines, a large amount of manual work is still necessary. Additionally, some producers offer individual design of the sled and seat.

The difference is noticeable, especially on the sled run. The sledding fun really begins with a sled from (South) Tyrol!

Recommended Producers

| Kathrein Rodel GmbH Gießenstraße 7 (Gewerbegebiet) A-6522 Prutz Tel. +43 (0)5472/6307 www.rodel.at Gallzeiner Rodelerzeugung Familie Helga & Bernhard Lederwasch A-6200 Buch 56 Tel: +43 (0)5244 / 65093 www.gallzeiner-rodel.at Josef Prantner Rodlbau Stainerstraße 16 6067 Absam Tel: +43 5223 - 575 39 http://rodlbauprantner.at Schiefer Rodel Haselstauderweg 2 I-39015 St. Leonhard in Passeier (BZ) Tel.: +39 0473 641 034 www.schieferrodel.com Aluminum sleds: Torggler Josef Alurodel Latzfons Dorfstr. 17 I-39043 Klausen - South Tyrol(BZ) Tel./Fax +39 0472 545047 Mobile +39 328 48 11 087 http://www.alurodel.com |

Bachmann Otto Rodelbau St. Silvesterstraße 30 - South Tyrol - Dolomites I-39038 Innichen / Winnebach (BZ) Tel. +39 0474 966700 www.bachmann-otto.com Georg Fluckinger Am Egererboden 20 A-6336 Langkampfen Tel: +43 (0)5332/87391 www.fluckinger-rodeln.at Peter Torggler Rodelbau Knottnerweg 4 I-39043 Klausen/Latzfons (BZ) Tel. +39 0472 545 117 www.torggler-rodelbau.com |

How do you like the content of this page?

How do you like the content of this page?

Please give us your feedback!

Vacation Offers